Margaritelli Lab

Our Test Center in Rodallo (TO) is equipped with the most advanced technologies and all the professional skills for tests in the field of railway superstructure. The laboratory is also accredited by ACCREDIA according to the requirements of the UNI CEI EN ISO/IEC 17025:2018 standard for carrying out static, dynamic and fatigue tests concrete sleepers compliant with standard EN 13230-2.

Our Test Center in Rodallo (TO) is equipped with the most advanced technologies and all the professional skills for tests in the field of railway superstructure. The laboratory is also accredited by ACCREDIA according to the requirements of the UNI CEI EN ISO/IEC 17025:2018 standard for carrying out static, dynamic and fatigue tests concrete sleepers compliant with standard EN 13230-2.

Quality control

Execution of routine tests on manufactured products for railways in series production according to the customer's technical specifications. Monitoring of the performances of sleepers and bearers during their working life cycle

Execution of routine tests on manufactured products for railways in series production according to the customer's technical specifications. Monitoring of the performances of sleepers and bearers during their working life cycle

Testing

Tests on manufactured products for railways,

fastening systems, concretes and elastomers.

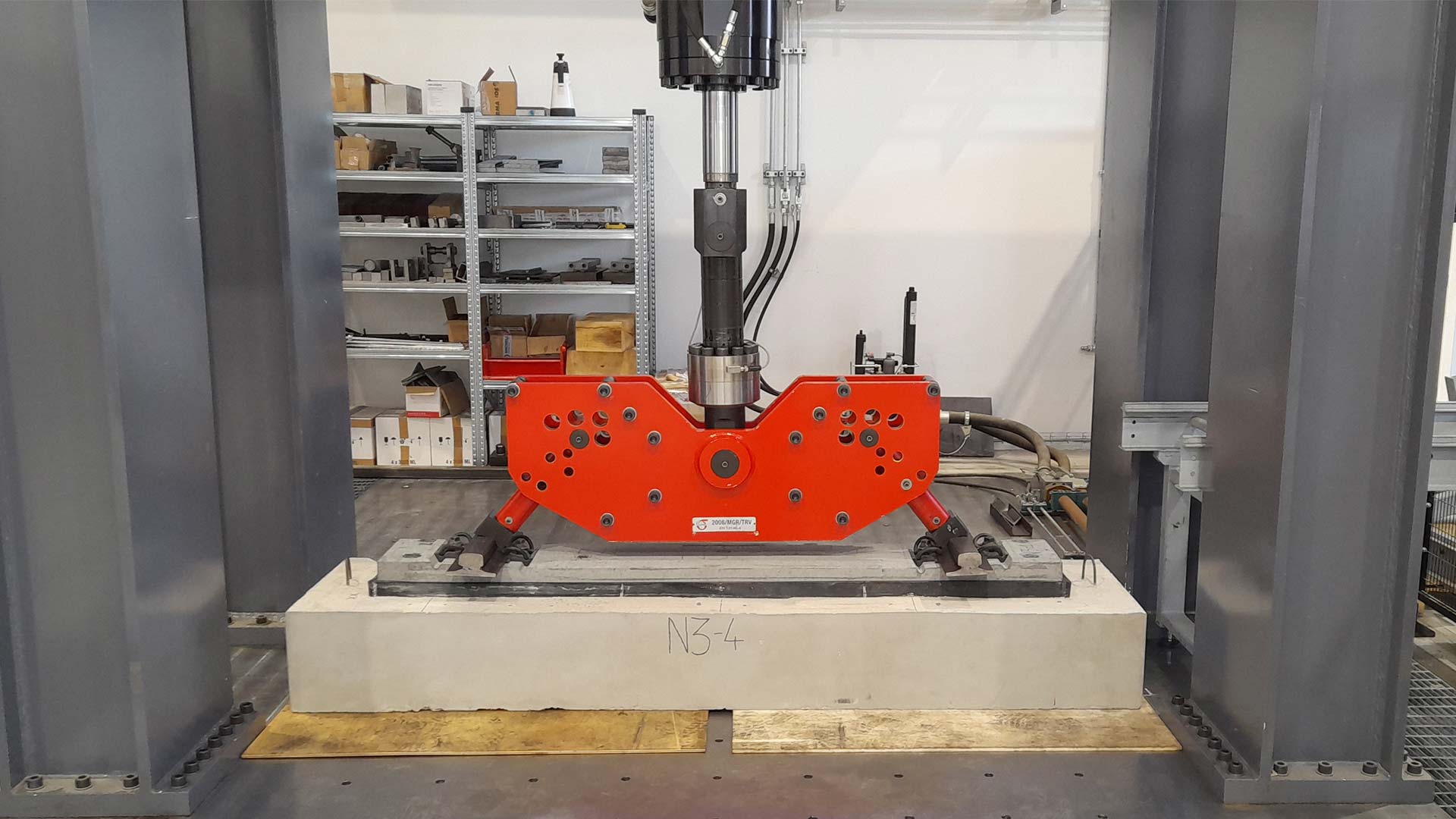

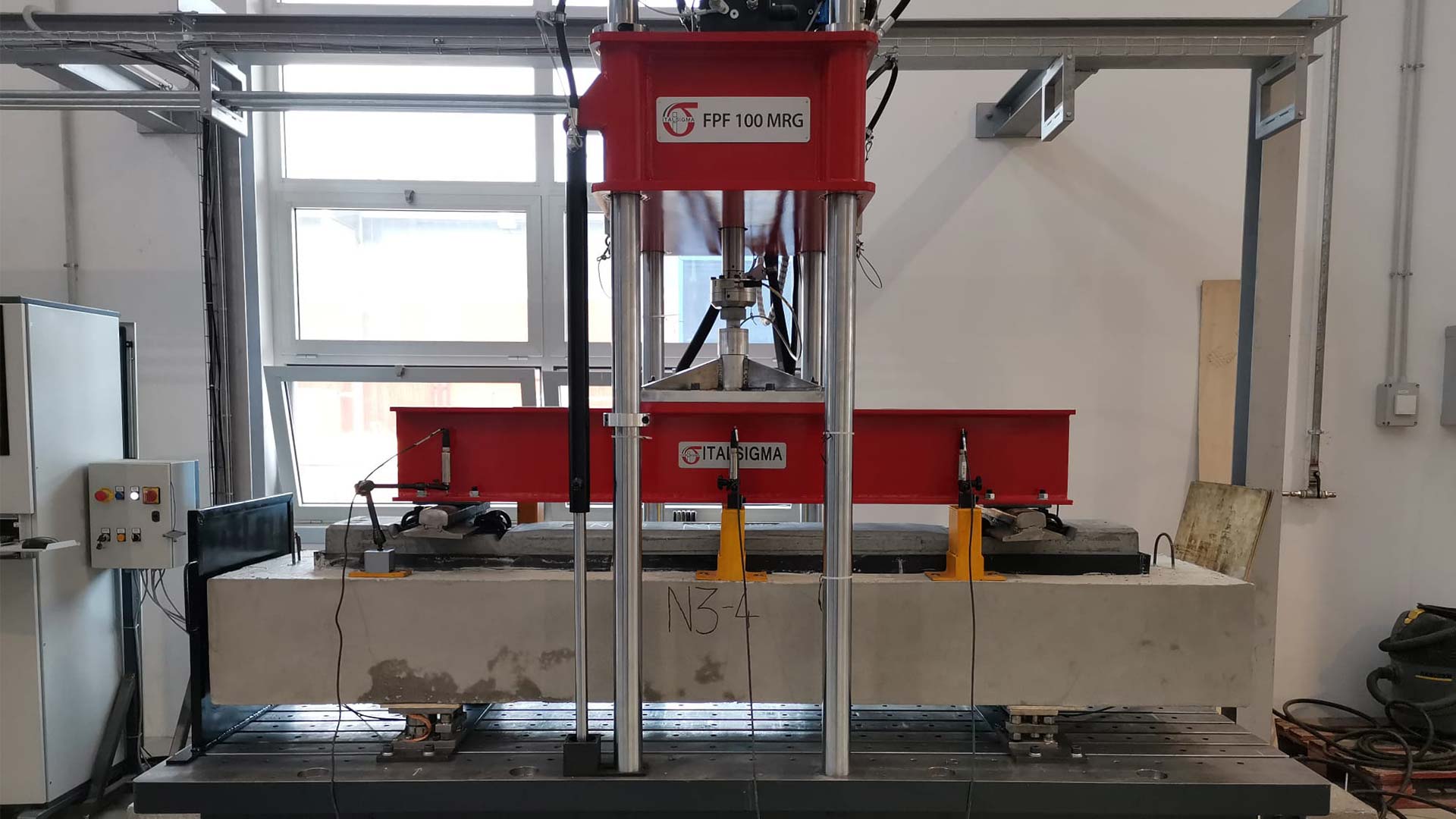

TESTS ON CONCRETE SLEEPERS

AND BEARERS ACCORDING TO EN 13230,

ACCREDITED BY ACCREDIA:

- Static test at the centre section for the negative load

- Static test at the centre section for the positive load

- Static test at the rail seat section

- Dynamic test at the rail seat section

- Fatigue test at the rail seat section

- Electrical resistance for fastening systems

TESTS ON CONCRETE SLEEPERS

AND BEARERS ACCORDING TO EN 13230,

ACCREDITED BY ACCREDIA:

- Static test at the centre section for the negative load

- Static test at the centre section for the positive load

- Static test at the rail seat section

- Dynamic test at the rail seat section

- Fatigue test at the rail seat section

- Electrical resistance for fastening systems

OTHER TESTS

ON RAILWAY

COMPONENTS:

- Dimensional Inspection

- Static and dynamic bending tests

on slabs for ballastless track systems - Static and dynamic characterization

of ballastless track systems - Dynamic tests with combined loads

on ballastless track segments simulating

the installation conditions - Test methods for fastening systems

Proof load test for pull-out resistance (UNI EN 13146-10) - Test methods for fastening systems

Effect of repeated loading (UNI EN 13146-4) - Compressive strength and tensile splitting tests

on concrete specimens - Water absorption tests of concrete

at atmospheric pressure - Pull-out tests on USP (Under Sleeper Pad)

- Water ingress protection test

Temporary water immersion - Static and dynamic

characterization tests of elastomers

OTHER TESTS

ON RAILWAY

COMPONENTS:

- Dimensional Inspection

- Static and dynamic bending tests

on slabs for ballastless track systems - Static and dynamic characterization

of ballastless track systems - Dynamic tests with combined loads

on ballastless track segments simulating

the installation conditions - Test methods for fastening systems

Proof load test for pull-out resistance (UNI EN 13146-10) - Test methods for fastening systems

Effect of repeated loading (UNI EN 13146-4) - Compressive strength and tensile splitting tests

on concrete specimens - Water absorption tests of concrete

at atmospheric pressure - Pull-out tests on USP (Under Sleeper Pad)

- Water ingress protection test

Temporary water immersion - Static and dynamic

characterization tests of elastomers

Margaritelli Ferroviaria - LAB

Margaritelli Ferroviaria - LAB

Margaritelli Ferroviaria - LAB

Margaritelli Ferroviaria - LAB

Margaritelli Ferroviaria - LAB

Research & Development

Thanks to the highly skilled personnel, to the availability of a big fleet of testing machines and to the state-of-the-art checking and sensor systems, the Margaritelli Ferroviaria laboratory is able to set up and carry out tests in a personalized and extremely flexible way - even on large sized products. - in order to continually improve its own products and to look for innovative technological solutions for railway systems.

Thanks to the highly skilled personnel, to the availability of a big fleet of testing machines and to the state-of-the-art checking and sensor systems, the Margaritelli Ferroviaria laboratory is able to set up and carry out tests in a personalized and extremely flexible way - even on large sized products. - in order to continually improve its own products and to look for innovative technological solutions for railway systems.